Engineering Waxes

Waxes are crucial to many engineering processes.

Our products in this sector are varied and include lubricants, corrosion inhibitors, masking waxes, and casting waxes.

Every batch produced by Darent Wax conforms to tight product specifications and is certified as such. ISO9001 accredited, our quality system shows complete traceability throughout our company.

We are keen to explore new applications, modify existing wax processes, or help with any challenges you may have.

A re-test and re-certify service is also available for existing customers.

-

Stopping Off Wax

Wilmask Protecto Waxes within the 11429 series have been produced for over 60 years. They are widely used throughout many industry types and are approved and used by leading manufacturers within the aircraft industry.

Read MorePlating Industry

The demand for rapid plating and the need to reduce production times has highlighted the requirement for a masking method with fast application times, fast removal times, and a good mask, with no cracking or lift from the masked surface. Protecto waxes from Wilkins Campbell are approved and used by leading manufacturers within the aircraft industry.

Limitations of alternative masking methods:

Time-consuming – whether it be masking tapes or lacquers, a lot of time and effort is unnecessarily wasted in application and removal.

Hazardous Waste – Solvents are required in many cases for removal of laquers/adhesive residue, and can be expensive to dispose of.

Expensive – most other masking products can only be used once, and are an expensive outlay for many plating businesses.

The Wilkins Campbell / Darent Wax Solution Wilmask Protecto Waxes have been developed in our laboratory to perfectly match the needs of the modern plater. Wilmask Protecto Waxes set off virtually instantly and usually only two dips are required, meaning more time is spent on the actual plating process leading to a more economical workshop. Wilmask Protecto Waxes are removed very easily: peeled/carved off, melted above the heated tank, or just melted off in boiling water.

Wilmask Protecto Waxes are ideal for high-detail work and sharp edges. Our products are low cost and re-useable (in most cases). Wilmask Protecto Waxes can be applied in a number of ways, and have been carefully formulated so not crack or ‘lift-off’ during plating.

Perfect masking every time.

-

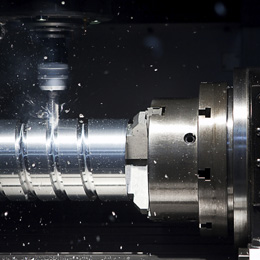

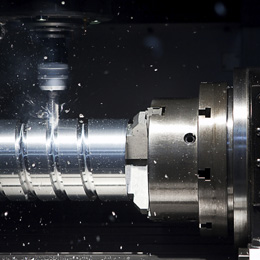

Blue Machinable Wax

Blue wax is a specially formulated machinable wax for use as a CNC program testing material.

Read MoreComponents can be produced with high definition and accuracy. Blue Wax allows program errors to be identified safely and eliminates the risk of damage caused by a tool / work piece crash.

Blue Wax can be reclaimed and used many times over – a feature which can reduce the test component cost to an insignificant level.

-

Green Machinable Casting Wax

Green wax is a specially formulated machinable casting wax for use as a CNC program testing material.

Read MoreComponents can be produced with high definition and accuracy. Green Wax allows prototypes to be produced by investment casting (lost wax process). Green Wax allows program errors to be identified safely and eliminates the risk of damage caused by a tool / work piece crash. Green Wax can be reclaimed and used many times over – a feature which can reduce the test component cost to an insignificant level.

-

Bronze Casting Wax

Sculpting or investment casting in waxes prior to metal casting is still a popular and effective method of producing art castings.

Read MoreDarent Wax has products to suit most applications. Features of our casting waxes include:

- Excellent dimensional reproducibility

- Low shrinkage

- Mechanical strength in the solid phase

- Low ash content

- Ideal surface texture and detail

- Stable

- Easy to handle

-

Saw Blade Lubricants and other Greases

We produce a range of superior quality greases with differing levels of hardness and melting points to cater for individual applications. If you would like advice or wish to discuss your application in more detail please do not hesitate to contact us.

Read More- Used extensively by the non-ferrous metal industry

- Extends the life of bandsaw blades, abrasive belts and discs

- Suitable for a range of metal polishing needs

- Available in a range of grades for specific applications and atmospheric temperatures.

- Available in a variety of formats, from small tubes to bulk drums.

-

Corrosion Inhibitors

Our Corrosion Inhibitors are designed to leave a thin film of grease over the metal component, providing complete protection from corrosove atmospheric conditions.

Read MoreTypical applications include weapon parts, vehicle parts, or sheet metal.

Our products conform to DEF STAN specifications, and we supply quality certified goods into a number of military stores globally.PX6 DEF STAN 91-38

PX11 DEF STAN 80-85

Available in a variety of packaging options from 500ml to 200L. Certificates available for each batch are available at no extra charge.